Does the Choice of Resin Matter?

Nowadays, there are a large number of different resins available. From harmless natural resin to epoxy resin and polyester resin, you can choose the resin that best suits your needs depending on the intended use. As a company, we have used a variety of different resins over time and can share some interesting information about them.

Natural Resin

When using natural resins, the primary focus is on environmental relief and the natural quality of all materials. Since these resins are produced naturally, there are no issues related to skin contact or fumes during the manufacturing process. The downside of these resins is that they often have a tint, are cloudy, or are difficult to work with, which made them insufficient for use in our artworks. As a result, we switched to epoxy resin. Another open question with all natural resins is their durability, especially when pieces cast from natural resin are stored outdoors, such as with a Chembuster.

Polyester Resin

We also resorted to polyester resin, which is commonly used in this industry, because we saw a clear price advantage over epoxy resin and were unaware of the concerning properties of polyester at the time. Polyester resin is currently the most widely used resin on the market due to its low cost. It has a rather unpleasant odor, which can persist even after curing and is due to the styrene it contains. What many people do not know is that the styrene in polyester is hazardous to health. Styrene is released into the environment even after the products are completed, especially if they are manufactured improperly due to a lack of knowledge. This can be easily detected through a smell test of the product (though the smell does not necessarily indicate styrene residues). Special processes like tempering (heat treatment) can convert the contained styrene, largely eliminating the odor caused by it. Another downside related to the quality of polyester resin was the durability of the cured resin. We made some of the first Chembusters from polyester resin and noticed significant cracks and fractures in the base after just a few years. These worsened over time, particularly in winter, causing the bases of the Chembusters to crack further until parts of them fell off. For this reason, we advise against using polyester resin. We are not experts in working with polyester resin, so the experiences described above may not be universal, and everyone should form their own opinion or seek information online.

Epoxy Resin

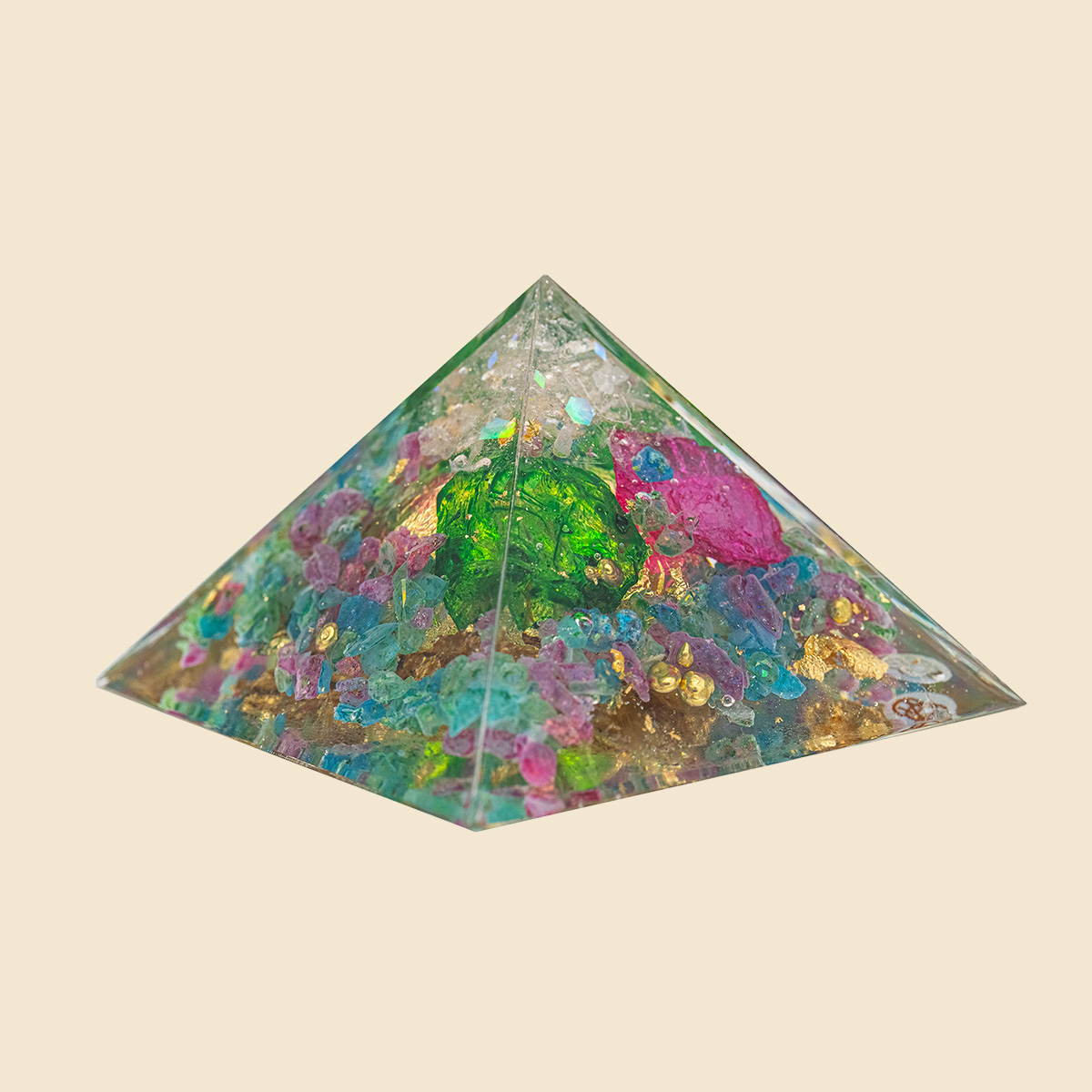

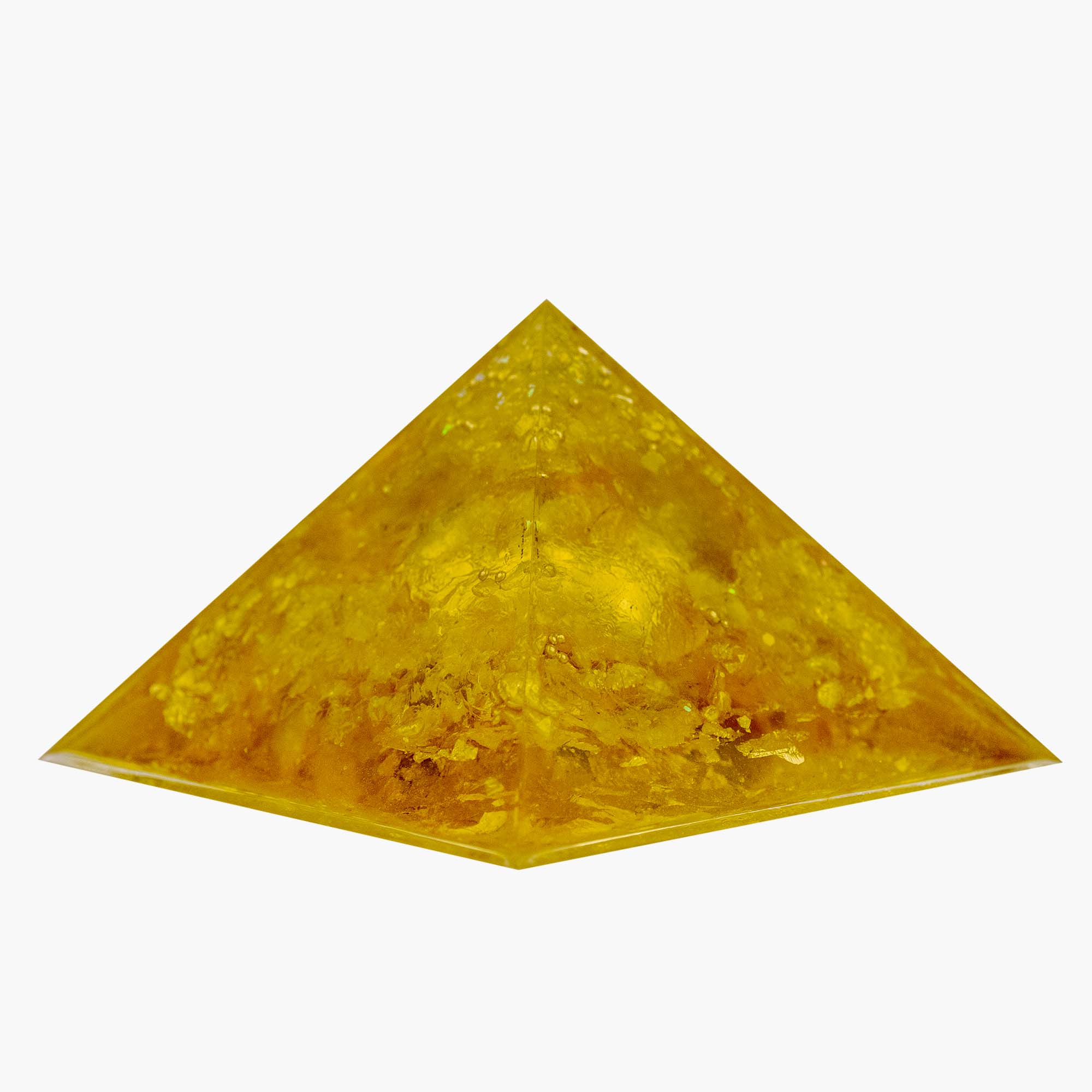

Our journey through the world of resins eventually led us to epoxy resin. Its crystal-clear surface, excellent durability, and food-safe properties after curing (only in certified resins) convinced us. Epoxy resin is also hazardous to health in its liquid state, so protective measures must be taken when handling it. However, when properly manufactured, this resin is odorless, tasteless, and has food-grade quality after curing, meaning you can safely make a drinking cup or plate from it. Of course, we conducted our own tests regarding durability. We placed several orgonites in the garden for years. With a few exceptions, they slightly yellowed but remained intact without cracks or material degradation, just like the bases of the Chembusters made from them. When using epoxy resins, it is also important to pay attention to the quality of the resin. Not every resin is good, and not every resin is food-safe. Therefore, it is essential to stay vigilant and be willing to spend a little more on a quality product to avoid facing negative consequences later on.